Key Benefits of Promag DCP

High Purity & Stability: Ensures consistent performance in polymerization and vulcanization processes.

Efficient Crosslinking: Enhances mechanical strength and environmental resistance of polymers.

Versatile Applications: Used in polymer, rubber, and industrial manufacturing for superior product quality.

Industrial Compliance: Meets stringent industry standards for reliability and efficiency.

With its outstanding properties, Promag DCP is a reliable and effective solution for manufacturers seeking high-performance polymer and rubber production. Its ability to optimize curing, crosslinking, and polymerization processes makes it a valuable asset for industries demanding superior product quality and durability.

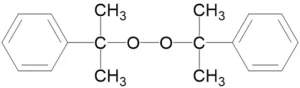

Organic Peroxide

Dicumyl peroxide

80-43-3

Crystal

270.4

1. Polymer Production:

Promag DCP is widely used in the production of polymers, contributing to improved durability, chemical resistance, and flexibility. It ensures efficient polymerization and consistent quality in high-demand applications such as packaging, automotive, and construction materials.2. Polymer Crosslinking:

As an effective crosslinking agent, Promag DCP enhances the structural integrity of polymers, offering increased resistance to mechanical stress and environmental factors. It is ideal for polyethylene and other high-performance polymers used in industrial and consumer goods.3. Rubber Production:

In rubber manufacturing, Promag DCP provides uniform curing and vulcanization, resulting in superior tensile strength, elasticity, and heat resistance. Its application is critical in the production of automotive tires, industrial seals, and other rubber components that require high reliability and performance.